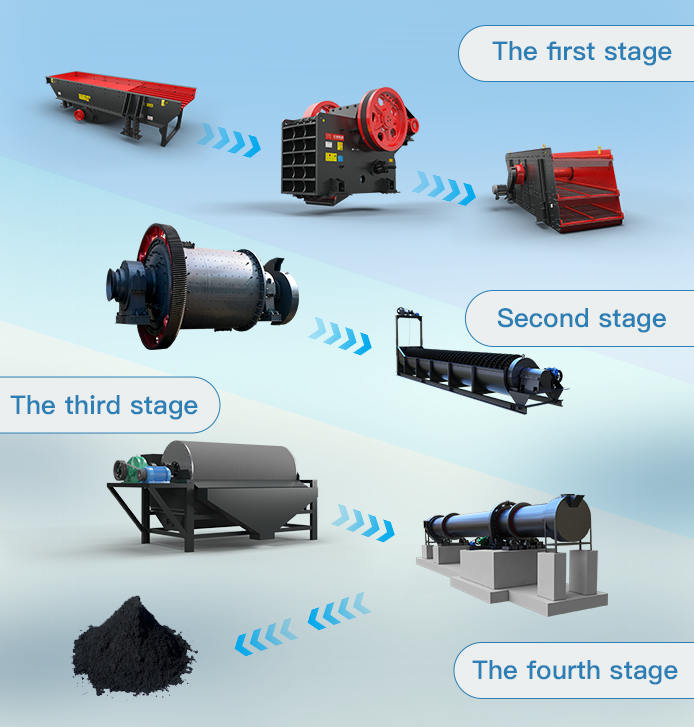

At present, the common iron ore is magnetite, limonite and hematite (collectively called weak magnetic ore). According to the magnetic strength of the ore, we choose different iron ore dressing processes. The magnetic separation process is used as the main method of iron ore beneficiation.

The iron ore process is advanced and the utilization rate of magnetite can reach 90%. And the configuration parts cited in the magnetite beneficiation production line are all wear-resistant materials, which can greatly improve the efficiency of the equipment.