Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.

Processing ability: 0.15-6 t/h

Spiral diameter: 300-3000 mm

Applied material:iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten, tin, tantalum, niobium, etc

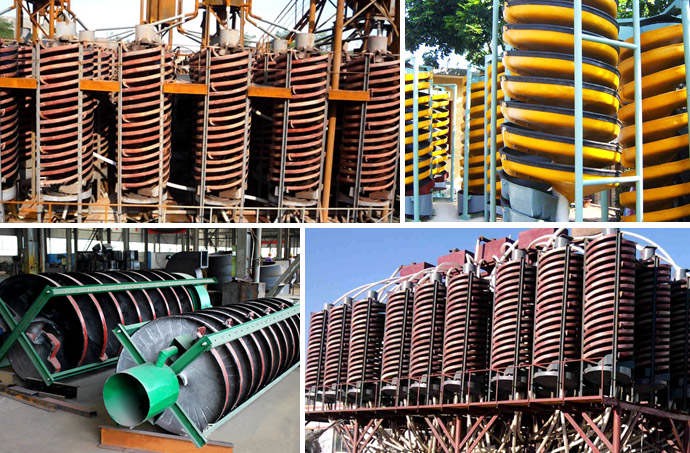

Spiral Concentrator which combines the advantages of spiral concentrator, shaking table and centrifugal concentrator, is a new beneficiation equipment with the advanced level. Spiral concentrator, as the scientific product based on production expertise, is the best concentrating equipment, especially for concentrating sand ore.

The product is made of the chlorine plastic which is light, moisture proof, antirust and corrosion proof and properly suitable for the changing of feeding size.

1. The spiral concentrator has a small footprint, moisture proof, antirust, corrosion resistance and no noise.

2. It consumes little water and electric power and has a large processing amount and low investment cost.

3. The ore dressing is stable; the mine is clear, and the recovery rate is high.

4. reasonable structure, simple configuration, easy operation and high efficiency.

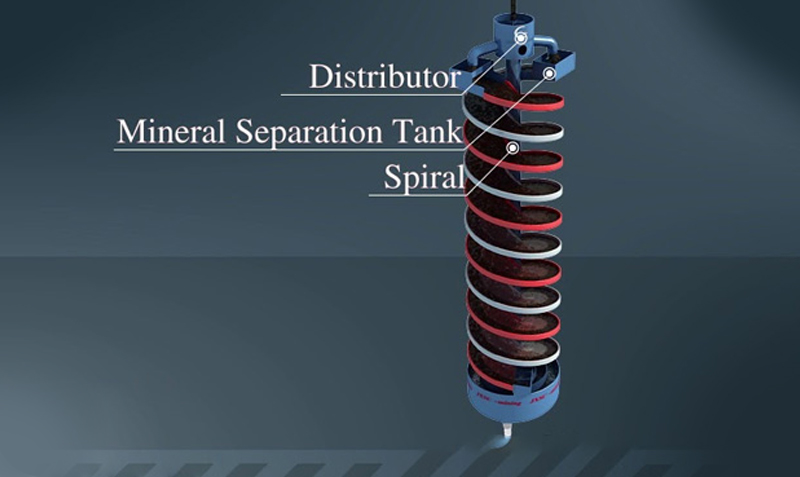

The spiral concentrator is installed vertically, and the ore is pumped from the sand to the two feed ports on the top of the spiral concentrator to adjust the density of the slurry. The ore pulp is naturally fed from high to low, and inertial centrifugal force is generated in the rotating inclined flow velocity.

According to the specific gravity, particle size and shape of the ore, the ore is separated by the gravity and centrifugal force of the cyclone separator. The concentrate flows into the concentrate hopper, which is connected with the pipeline. The tailings flow into the tailings hopper, are connected to the sand tank through pipelines, and are discharged by the sand pump. The whole beneficiation process has just been completed.

1. Rutile, ilmenite and zircon concentration

2. Iron ore, chromite and manganese beneficiation

3. Tin, tantalum and ore concentration

4. Gold, native copper and base metal recovery

5. Silica sands processing

6.Titano-magnetite concentration

Latest Price List/Free Customized Solution/Maintenance & Installation Guide

Customize different models according to your needs(Small, medium, and large machine).

We have three production bases, guarantee 100% factory price of all products, and support export to all over the world.

We have professional customer service staff, ready to answer your questions about our products.

| Model | Processing capacity (t/h) |

| DL2000 | 15-40 |

| DL1500 | 8-16 |

| LL1200 | 4-6 |

| LL900 | 2-3 |

Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.