Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.

Ball mill is the key equipment for grinding crushed ores/stones (input size≤25mm) into ore powder (150-200mesh) or ore pulp while adding water.

Ball mill has a strong adaptability to many kinds of materials in different areas.

Applied Materials

Ball mill can grind various ores/stones. Common materials include gold ore, copper ore, chrome ore, iron ore, manganese ore, lead ore, nickel ore, zinc ore, tin ore; granite, limestone, silica, quartz, gravel, slag, aggregate, gypsum, cement, clinker, kaolin, feldspar, sand, pebble, glass, fly ash, coal, phosphate, bauxite, carbon, marble, dolomite, calcium carbonate, soft stone, clay, ceramic, bentonite, black stone, etc.

Applied Areas

Ball mill is applied widely in many industries, for example, cement industry, silicate products, new construction materials, refractory materials, fertilizers, ferrous and non-ferrous metal ore beneficiation, and glass ceramics production industries.

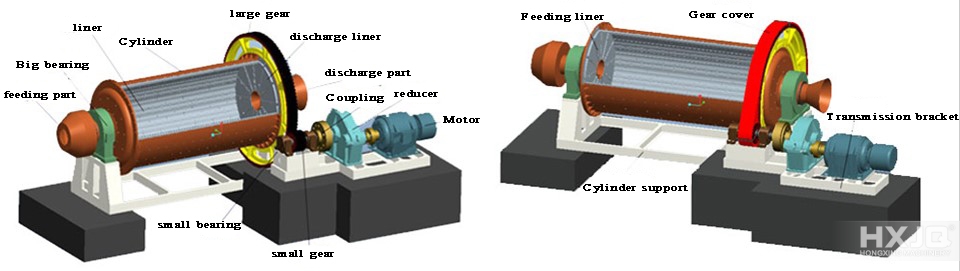

Ball mill machine includes feeding device, rotary part, discharging device and transmission.

1. Feeding Device

For drum feeder, the flange on the feeder is connected with the hollow shaft at the feeding end. There is a spiral cylinder for feeding in the hollow shaft, and the material enters the mill through this.

2. Rotary Part

It is a cylinder body welded by steel plates. The two ends are respectively connected with the hollow shaft for feeding and discharging by bolts. The large gear fixed at the discharge end of the cylinder meshes with the small gear decelerated by the motor through the reducer to rotate.

3. Discharging Device

It is a discharge screw barrel with a bell mouth. The flange on the device is connected to the hollow shaft at the discharge end, and the material is discharged through this.

4. Transmission Part

The power of the mill is transmitted through a pair of large and small gears. The large gear is connected to the barrel through the flange on the barrel. The small gear is supported by a pair of rolling bearings and connected to the reducer and the motor through a coupling.

There are feeding liner, tube liner, compartment plate, and discharge liner in ball mill machine.

1. Feeding liner, also known as end lining, is made of high manganese steel without hollowing.

2. Tube liner can protect the barrel from abrasion and bring the grinding medium to a suitable height to achieve the best grinding.

According to materials, tube liner can be devided into manganese steel liner, rubber liner and ceramics liner.

Tube liners features:

Manganese steel: high output, most commonly used

Rubber: high abrasion resistance, low noise, corrosion resistance, but slightly lower output

Ceramics: prevent iron pollution, high cost

By shape, tube liner has corrugated liner and step liner.

3. Compartment plate: high manganese steel, with holes, the position can be adjusted according to production needs.

4. Discharge liner: blind liners and rafters

Generally, the thickness of the lining plate is determined according to the diameter of the mill, which is generally between 50-150 mm.

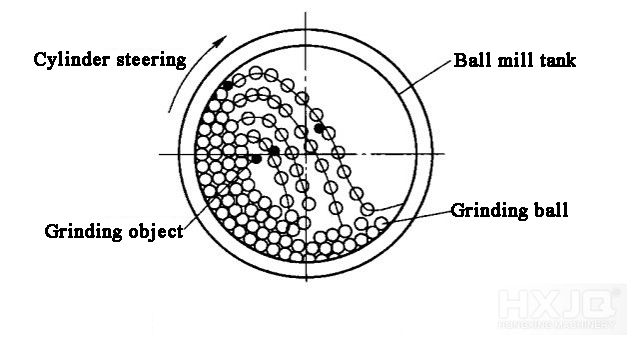

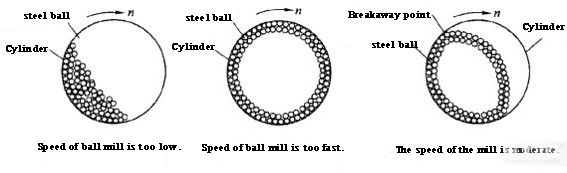

The ball mill is a horizontal cylindrical rotating device, which is driven by the outer gear. The material is spirally and uniformly entered into the mill from the feeding device through the hollow shaft. The wear-resistant lining is installed in the warehouse. The centrifugal force brings the steel ball to a certain height and falls, which has a heavy impact and grinding effect on the material. The powder is discharged through the discharge grate plate to complete the grinding operation.

Steel ball and ceramic ball are commonly used as ball mill grinding medium. There also are other grinding mediums like steel segment and steel rod (used in rod mill).

According to the process conditions, ball mill can be divided into:

1.Dry-type ball mill: Grinding the material to meet the requirements of ore powder, usually a double or three bin structure.

2.Wet ball mill: The material is ground into a certain concentration of pulp.

According to the structure, ball mill can be divided into:

1.Lattice ball mill: Ladle board, the spiral direction of the discharge port is the same as the inlet, so that the slurry is discharged, which has the effect of forcing the ore discharge, can reduce the over crushing of the ore, and has a higher production capacity, but the product size is larger than that of the overflow mill These are often used in the first stage of grinding operations. The disadvantages are that the structure is complicated, the grid type drainage is easy to block the grid plate, and it is difficult and complicated to repair.

2.Overflow ball mill: Blind lining board, the spiral direction of the outlet is opposite to the inlet, so as to prevent the steel balls and ore blocks from being discharged from the machine with the pulp. The relative grinding time is long, and the ore can be fully ground and stayed in the machine. The time is also long, so the grinding product is fine, so it is suitable for the second stage grinding in the two-stage grinding process, and the role is to re-ground the intermediate product to obtain a fine-grained qualified product. However, the production capacity per unit volume of the machine is low, and it is prone to over-pulverization.

According to work continuity, ball mill can be divided into:

1.Intermittent ball mill: also known as ceramic grinding, discontinuous work, mostly used for grinding materials that require higher fineness. Ceramic ball mill is the ball mill with the liner made of ceramic.

2.Continuous ball mill: can work continuously for 24 hours

Henan Hongxing Mining Machinery Co., Ltd.(HXJQ) is a manufacturer of high-end mining machinery in China and covers an area of 350,000 square meters which includes 260,000 square meters of heavy duty industrial workshops. HXJQ has the price advantages of China factory direct sale price, lowest competitive price with same quality of machines, and latest discount available for online customers.You can leave message online, contact us online directly or send email to us to get latest free quotation.

Prev : High Quality of Slime Dryer Manufacturers

Next : Raymond Mill

Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.