Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.

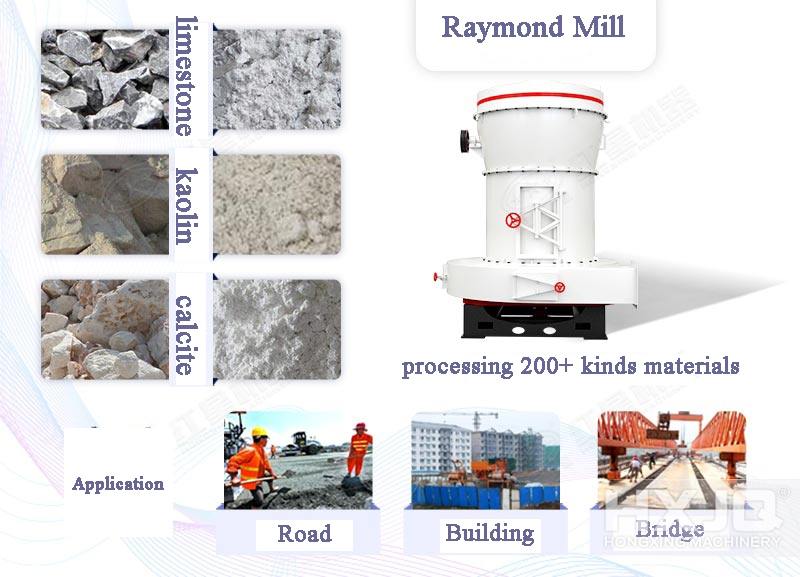

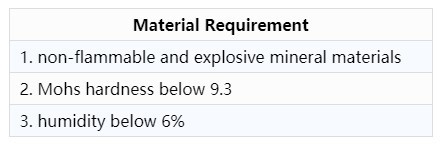

Raymond mill is mainly suitable for grinding and processing of mineral materials such as metallurgy, building materials, chemicals, mines, etc., it can grind quartz, feldspar, calcite, limestone, talc, barite, fluorite, rare earth, marble, ceramics, bauxite, manganese ore, iron ore, copper ore, slag, water slag, cement clinker, dolomite, granite, garnet, fly ash, bituminous coal, coking coal, lignite, gold ore, red mud, clay, kaolin, coke, coal vermiculite, porcelain clay, kyanite, fluorite, bentonite, maifanite, rhyolite, turbidite, pyrophyllite, shale, purple sandstone, turbidite, diceite, basalt, gypsum, graphite, silicon carbide, thermal insulation Processing of various non-flammable and explosive mineral materials with Mohs hardness below 9.3 and humidity below 6%.

Highlights:

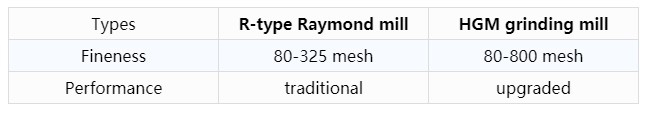

HXJQ's Raymond mill mainly include traditional R-type Raymond mill and HGM German version of high-efficiency ultra-fine mill. R-type Raymond mill is a traditional and commonly used grinding mill. R-Raymond mill is widely used in non-flammable and explosive mineral chemical, construction and other industries of more than 280 materials for high-precision powder milling processing. The particle size of the finished product can be adjusted arbitrarily within the range of 80-325 mesh. HGM high pressure fine grinding mill is based on more than 20 years of research and development experience of grinding equipment in our company's research institute. According to the actual use of grinding equipment by users for many years, to meet the needs of the development of the milling industry, it absorbed the better milling technology and concepts at home and abroad, and developed new products with high technical level with great concentration. The finished fineness of the material can be arbitrarily adjusted between 0.18 mm (80 mesh) to 0.010 mm (800 mesh).

Highlights:

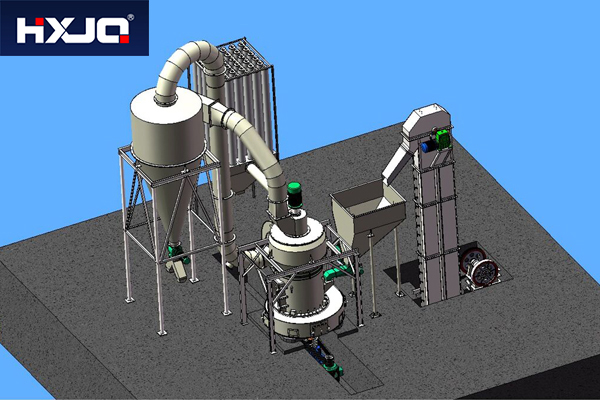

It mainly consists of host machine, fan, powder separator, cyclone powder collector, dust collector, pipeline device and motor. The main unit consists of a frame, an air inlet volute, a shovel, a grinding roller, a grinding ring and a cover. Supporting auxiliary equipment also includes jaw crusher, bucket elevator, electromagnetic vibration feeder, silo, power distribution cabinet, etc.

Crushed material is sent to the storage hopper by the bucket elevator, and then fed into the host by the electromagnetic vibration feeder for grinding. The grinding roller device suspended on the plum frame in the main machine rotates around the central axis, and the grinding roller rotates around the grinding roller axis at the same time. Under the action of centrifugal force, the grinding roller swings outward to press the grinding ring, and the material scraped by the rotating blade is tossed between the roller rings, because of the rollers grinding to achieve crushing and grinding. The powder in the grinding chamber is blown to the analysis machine above the main unit for analysis by the airflow of the blower. Too coarse powder still fall into the main unit and reground. The powder whose fineness meets the specifications enter the large cyclone collector with the airflow. The discharge of the material pipe is the finished product. The air flow of the machine circulates and flows in the fan shell cyclone separator fan, so it produces less dust.

Hongxing Mining Machinery Co., Ltd (HXJQ) focuses on the production of grinding equipment for more than 40 years, has a very good market reputation, and is a reliable manufacturer for users. Our products are sold to more than 160 countries like India, Nigeria, Pakistan, Egypt, Indonesia, Saudi Arabia, etc. and our business scope is worldwide. The quality and service of our products are highly recognized and affirmed by customers at home and abroad.

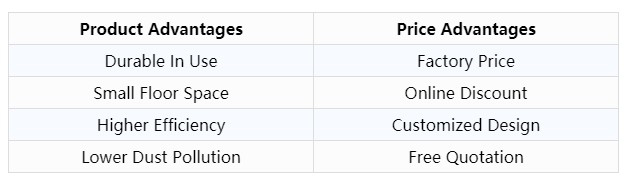

Our Advantages

Our Service

Welcome friends from all over the world. We are always here waiting for your consultation. Contact us online.

Prev : Ball Mill

Next : Rotary Dryer

Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.