Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.

Rotary dryer is mainly used to dry materials with a certain humidity in the ore dressing, building materials, metallurgy, chemical and other departments. The size of the dried material is generally not more than 50mm. The series of dryers produced by Henan Hongxing are widely used for drying iron oxide scale, sludge, coke, pig iron scrap, copper concentrate, silicon carbide powder, rare earth ore, mercury ore powder, tin ore powder, cobalt ore powder, nickel ore powder, manganese ore powder, gypsum powder, bentonite, kaolin, lead concentrate, petroleum coke, gold ore powder, steel slag, water slag, fluorite ore, sea sand, river sand and other materials.

According to the structure, the rotary dryer can be divided into a single-cylinder dryer and a multi-cylinder dryer. The multi-cylinder dryer includes a double-cylinder dryer and a three-cylinder dryer.

According to the heat transfer method, the dryer can be divided into a direct heat transfer dryer and an indirect heat transfer dryer.

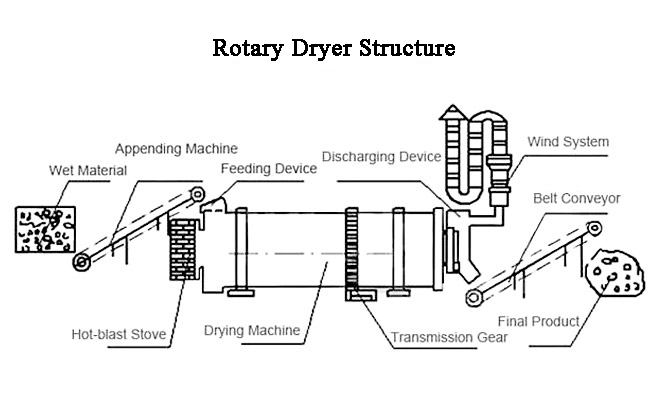

The rotary dryer is mainly composed of a cylinder, a supporting device, a transmission device and ancillary equipment.

Cylinder: It is welded by steel coils, a spiral plate is welded at the feeding end, a lifting plate is welded at the middle of the cylinder, and a ring-shaped material blocking ring is welded at the discharge end. The cylinder is inclined 5% from the level. The lifting plate is generally welded directly into the cylinder. If the customer requires it, it can also be produced into a bolt connection. The angle of the lifting plate is generally 90°, 135°, 150°, etc.

Supporting Device: The belt on the barrel rotates with the cylinder. The supporting roller supporting the belt is mounted on the frame. In order to limit the axial movement of the cylinder, a blocking wheel is also installed on the frame, and the inclined surface of the blocking wheel has a gap of 5 mm from the inclined surface of the belt . The amount of movement of the cylinder in the axial direction is controlled within 5mm. Fill the groove of the bracket with water and add oil to the water is to cool the idler and the belt and have the function of lubrication.

Transmission Device: The large gear sleeved on the cylinder is fixedly connected to the cylinder, and the large gear is driven by the small gear. The motor drives the cylinder through a V-belt, a reducer, a small gear, and a large gear to perform rotary motion.

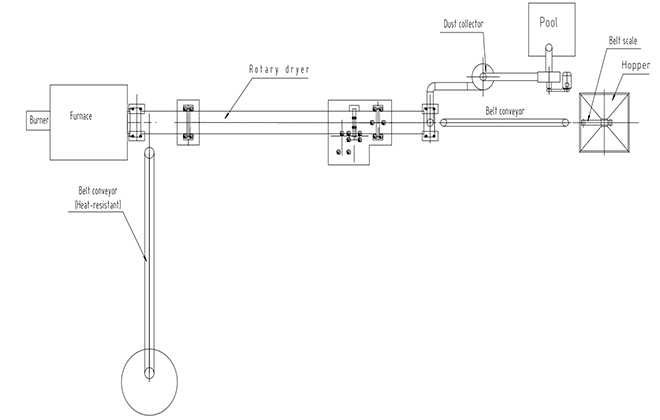

Ancillary Equipment: feeder, feed conveyor, discharge conveyor, induced draft fan, hot blast stove and dust collector.

During the process of the material entering the cylinder and moving along the axis of the cylinder, on the one hand, material is heated by the cylinder, and on the other hand, it is exchanged with hot air during the process of being lifted by the lifting plate. The moisture of the wet material is evaporated during the heating process, and the moisture content is gradually reduced.

The heat source used by the dryer is natural gas, coal, electrical energy, etc. At the same time, the selection of the heat source of the dryer also affects the operating cost of the dryer. When selecting a heat source for a dryer, you must select a suitable heat source in accordance with the local conditions, the safety of the heat source, environmental requirements, etc.

1.Downstream

2. Countercurrent

There are many rotary dryer manufacturers in the market. Here we recommend the Henan Hongxing machine for users. The main reasons for recommending this manufacturer are:

Reliable Quality: Not only does the manufacturer have large and modern equipment production workshops, but also the selection of equipment operators and raw materials is very strict, ensuring that each piece of equipment produced has excellent quality.

Complete Service: Help users choose the right equipment in the early stage, install and debug the equipment selected by the customer in the medium term, and return a visit, answer the problems existing in the customer's operation in time, effectively reducing equipment downtime and reducing investment costs in late period.

Affordable Price: The manufacturer has its own production workshop, and the production and sales of the equipment are completed by itself. There are no middlemen to earn the difference. The price of the equipment sold is equivalent to the factory price.

If you want to know more about rotary dryer and its price, please contact us online get latest price for free.

Prev : Raymond Mill

Next : Copper Ore Processing Plant

Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.