Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.

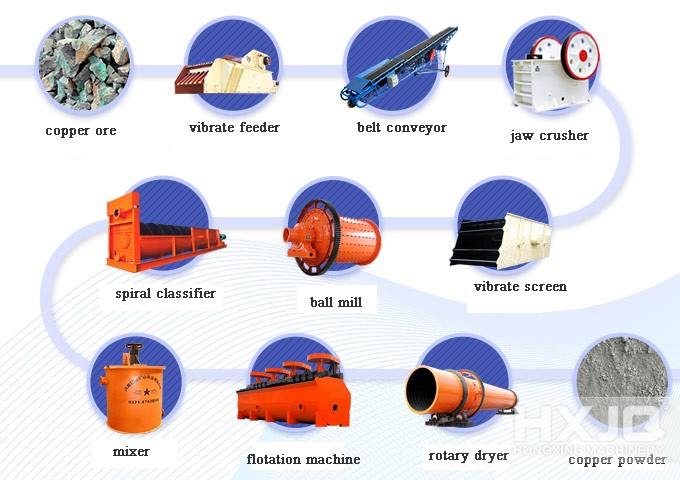

Copper ore undergoes a series of beneficiation and smelting treatments to obtain copper metal with a wide range of uses, which is widely used in electrical, light industry, machinery manufacturing, construction, chemical and other industrial sectors. Copper ore exists in many forms in nature, including chalcopyrite, chalcocite, bornite, etc., with good mining value. For its copper separation equipment, HXJQ manufacturers combine the characteristics of copper ore to professionally design and produce series A complete set of copper selection equipment such as ball mills, flotation machines, rotary dryers, jaw crushers, spiral classifiers, mixing barrels, concentrator, etc., with complete types and high quality.

Flotation is generally used to extract concentrate from copper ore. Therefore, the entire copper ore beneficiation process includes grinding equipment, flotation equipment, classification equipment, drying equipment and so on.

1. Crushing: The jaw crusher is used to crush the raw ore to a suitable size, and the simple dissociation of the ore is initially realized. Some copper mines will use two-stage crushing, and an impact crusher is added after the jaw crusher to further crush the ore;

2. Grinding: The crushed copper ore crushed stone is evenly sent to the ball mill for further grinding treatment to obtain a smaller size of copper ore powder to achieve complete dissociation of the ore, which is classified by the spiral classifier, and the non-conforming ore is returned to regrind in ball mill.

3. Flotation: The qualified copper ore powder (slurry) obtained by grinding is sent to the mixing tank and mixed with the reagent, and then enters the flotation machine to produce a chemical reaction to obtain a good separation of the copper concentrate;

4. Dehydration: The copper concentrate slurry obtained by flotation enters the thickener to fully concentrate and settle, and then is dehydrated and dried by the dryer, and basically high-grade copper concentrate powder can be obtained.

Advantages of copper ore production line

1. The production line is reasonably equipped, the space layout is compact, the investment is reduced, and the operation is simple;

2. High-energy, high-yield, good flotation effect and improved concentrate grade;

3. There is not much production pollution, the backwater from the beneficiation is recycled and the tailings are properly treated, which will not affect the production environment;

4. Tailor-made design is more suitable, reducing customer investment and improving production efficiency.

Pakistan copper ore processing project: The copper ore in this project is chalcopyrite, with a copper content of 0.47%. The gangue minerals are mainly quartz, plagioclase, etc. The beneficiation process is more complicated. After the HXJQ manufacturer understood the needs of the customer, he designed a reasonable and economical copper ore beneficiation production line and equipped with a complete set of complete copper separation equipment, which fully realized the comprehensive recovery of copper minerals and improved the 30%-50% of flotation grade in the use of the production line, it is energy-saving and environmentally friendly, and has a very good use effect, creating a lot of economic benefits for investment users!

Customer Reviews:

We are very satisfied with the copper ore flotation production line designed by Henan HXJQ Machinery. The products produced by this production line have uniform grain shape and high grade, which are very competitive in the market, and the entire production line has good sealing performance. The production process is relatively good. HXJQ manufacturers not only designed a production line that can make money for the company, but also the after-sales service is very considerate. I am very happy to choose to cooperate with HXJQ at the beginning.

Henan Hongxing Machinery Factory (HXJQ) has focused on the production of copper ore beneficiation equipment for more than 35 years, and has produced a complete set of high-quality copper beneficiation equipment. It will design more suitable copper beneficiation production lines for customers according to the nature of copper ore in different regions, and ensure that the investment is not much. For more information about copper flotation equipment, please consult online!

Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.