Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.

In the rough selection and selection of copper, zinc, lead, nickel, gold and other non-ferrous metals and ferrous metals from ores, flotation production process is suitable for processing various ultrafine and fine ore powders. The flotation process is one of the most important and widely used processes in beneficiation production, and more than 93% of the beneficiation operations are processed by flotation production.

The flotation production line is efficient and energy-saving, and the energy saving of the flotation machine can reach 60% , the amount of flotation agent is reduced by 20% , and the recovery rate is increased by 1% ~ 5% .

Customer Revenue

1. The flotation production line not only reduces the investment cost for customers, but also has a large annual output and quick returns.

2. In the entire production line, the machine uses high-strength wear-resistant materials, with low loss and long service life, which can bring considerable economic benefits to customers.

Solution Design

According to the environment, geology, climate, planning scientific and reasonable production line process for customers, HXJQ tries to achieve the pre-sale service, sales service, and after-sales service commitment.

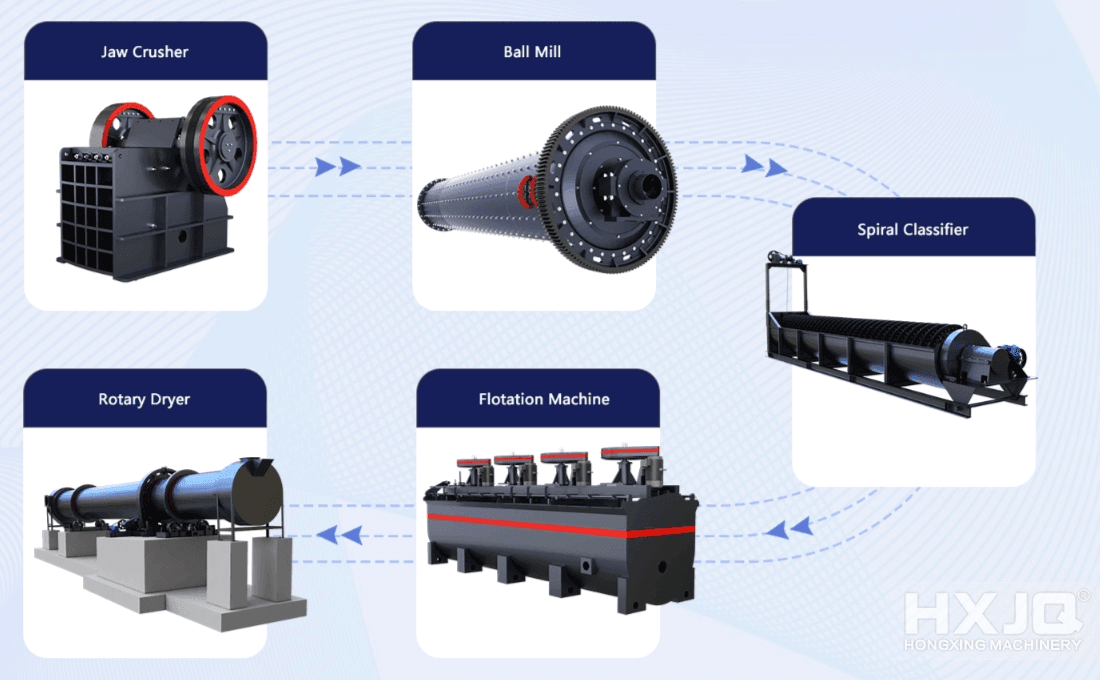

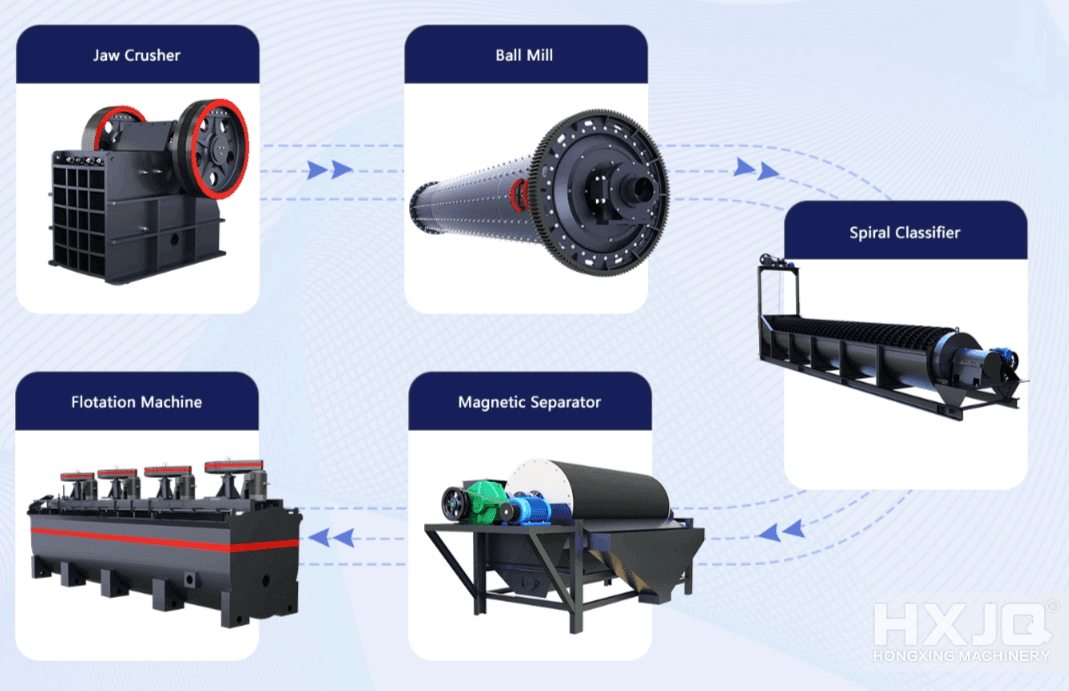

The flotation equipment is mainly composed of jaw crusher, ball mill, spiral classifier, flotation machine, and high-efficiency concentrator. There are various types of flotation machine. SF flotation machine, BF flotation machine are a new type of self-priming flotation machine; inflatable mechanical stirring flotation machine is currently the most competitive flotation equipment, which has simple structure, low impeller speed, low energy consumption and other advantages.

The main factors affecting flotation processing include grinding fineness, slurry concentration, dosage of reagent, aeration volume, flotation time, etc. Usually, these process conditions require beneficiation tests to determine.

Solution One

Gold ore flotation process

Flotation is the most widely used beneficiation method for processing gold mines at gold beneficiation plants. It is often used to process gold ores containing sulfide minerals with high floatability. The flotation process can maximize the enrichment of gold into sulfide minerals, the tailings can be directly discarded, and the cost of beneficiation is low. The flotation process mainly includes several stages such as dosing, stirring, aeration, and foaming.

Solution Two

Copper ore flotation process

The flotation (concentration) process of copper ore is generally divided into crushing, grinding, flotation, drying and other processes. The specific process steps are as follows:

If you are interested in our machines and their price, contact us online for 2020 latest price list!

Prev : Gold Mining Equipment Price

Next : Buying Raymond Mill

Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.